My last post about the light restoration of the Seiko 7019-7070 seemed to have a bit of interest so I thought I’d do this again with my next project, a Seiko 7019-7060 from September 1976.

This Actus wasn’t in very bad shape overall so I expected that it would be a simple project. It did not run and the glass had some distracting scratches but the dial, hands, case, and movement seemed to be in good shape still. A rattling and metal on metal dragging sound could be heard when the watch was shaken so something was definitely loose inside. While shaking it I noticed that the second hand would start moving occasionally but would immediately stop. Putting it into the winder seemed to do nothing for it so I suspected that the loose piece inside must be the autowinding rotor.

Doesn’t look too bad. Scratches on the glass are distracting so I’ll try to do something about that.

Here are a couple of pictures of the watch opened up. I think they are fairly self explanatory.

I confirmed that the rotor was mostly unscrewed from the movement. The gears on the bottom of the rotor most likely were not engaging the rest of the automatic winding system. This was demonstrated in the following pictures with the shake being obvious in the circled area.

The rotor is almost completely unscrewed. There was a lot of extra movement as shown in the red circled area on these two pictures.

The rotor is almost completely unscrewed. There was a lot of extra movement as shown in the red circled area on these two pictures.

I removed the rotor to identify what the metal on metal dragging sound was. The red arrows point out all of the areas that looked like the rotor was rubbing on. Most of this looks cosmetic except maybe the the gear I pointed out; that turned out to just be old lubricant and filth and it cleaned up nicely.

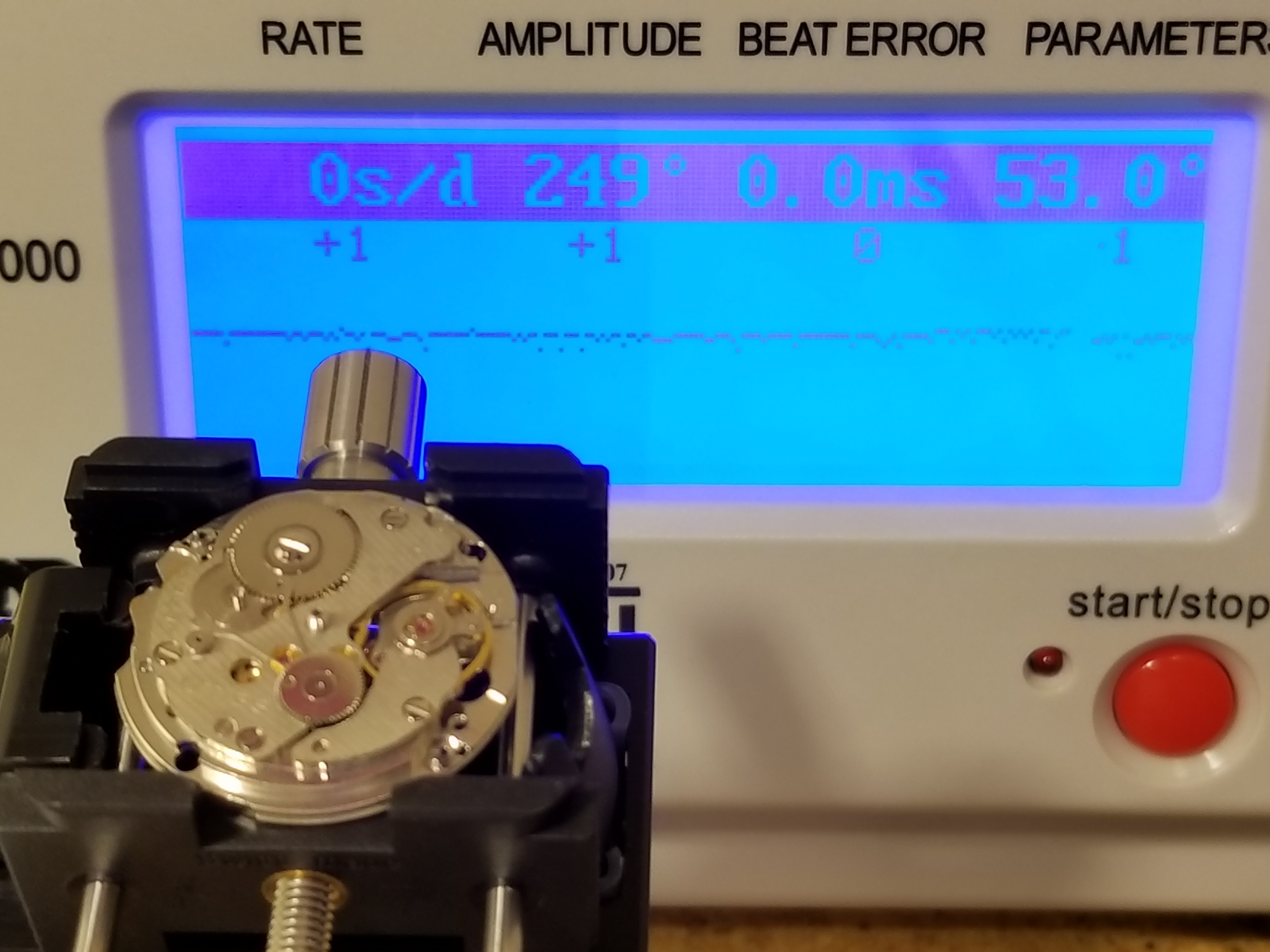

With the weight removed I was able to wind it up fully and it started running. I put it on the timegrapher and it looked surprisingly good aside from the basic symptoms of a dirty movement. This basically confirmed that this would be a simple clean and oil to finish things up.

Fully wound on the timegrapher. This looks pretty good aside from the symptoms of needing a good clean and lube.

Here is the mainspring which looks worse than it really is because the grease Seiko uses is a grey/black color. However, it is still gummed up with broken down grease and oil which prevents a lot of power from making it to the train of wheels. This is probably the biggest contributor to the very low amplitude displayed on the timegrapher. Once I got the spring out of the barrel I discovered that it still looked perfect in shape so this will be cleaned up and reused.

Mainspring is losing a lot of power gumming through this crap inside. This is just old lubricant which has degraded over the years.

Here is the movement disassembled and getting prepared for cleaning.

Sorry folks, this is about the time that I got carried away and forgot to snap some pictures of this process. Here is the movement reassembled and being adjusted on the timegrapher.

Mostly reassembled and being checked on the timegrapher. The trace could probably be smoother but for its age and cost this is good enough for me!

I stripped the case apart and the seals were so filthy that the ultrasonic cleaner and regular solvents weren’t doing the job so I had to figure something else out. I eventually tried some Brasso on a toothpick to slowly clean off the corrosion and filth from the case seals which through a bit of patience did the job. The finish on the case itself looked good enough to me after taking a cycle in the ultrasonic so I didn’t need to touch anything up or use any polish. Finally, I tried to polish the original glass but as usual with hardlex this was useless and I ended up replacing it.

Here it is with a strap. I’ve been wearing it daily for about a week and so far is keeping time to about -7 seconds per day.

I think this turned out well and coincidentally gave this watch a nice birthday present. Thanks for looking!

Site Feed

Site Feed

Hi,

Cool watch blog.

How can I tell the age or manufacture year on a Seiko 5 Actus 7019-7060. Are those all 1976?

Thanks Peter

Sorry for the delay in getting back with you. I imagine by now you’ve found your answer but I’ll reply just in case someone else stumbles across this. The folks at watchsleuth.com published a great resource for figuring out the approximate date of these watches: http://www.watchsleuth.com/seikodatefinder/

Hi, thanks for uploading this information. Any tips for replacing the main spring on this watch? The first time I tried reinserting this spring by first slipping it into the retaining spring anchored to the mainspring barrel and then winding it in by hand, I realized somehow I had put it in in reverse! Which I can’t figure out how I was able to do since there only seemed to be one way of putting that spring in given the opening on the little retaining spring and how it’s oriented. The second attempt I managed to snap off the little strip of spring soldered to the inner wall of the mainspring barrel. Also did you apply any breaking grease, even though the end of the mainspring seems pretty well locked in place with that retaining spring? Thanks a lot and advance!

I think I figured out what happened. What I thought was attached to the inner wall of the barrel was just the mainspring bridle, which must have been broken from the mainspring and somehow remained in the barrel when I removed the spring. On another note, I’m wondering which tool you used to press the bezel in place after replacing the faceted crystal on your Actus?

Apologies for the delay in replying.

Reinstalling a spring is very difficult to do without causing the sorts of trouble you have run into. There are winders that I have had poor results with so I usually just use my fingers when doing this.

Regarding your scenario… I recommend taking a photo of the mainspring inside the barrel before removing it to use as a reference for the proper direction. In your case this is no longer possible but you can reference the photo in this blog post. I normally expect to have to replace the mainspring every time I service a watch. I should have this mainspring documented in my reference page if you want to order a replacement for your watch.

I use a variety of cheap crystal presses to snap the bezel back on. I usually put a microfiber towel, like what you would use to clean glasses with, between the nylon die and the watch to give a little extra cushioning. I just use trial and error to select the right sizing and a little caution to avoid breaking the glass or scratching anything.

Good luck on your project!

What are the specs for the specific crystal if you are going to replace it? Is there a specific size or perhaps a number to buy after market crystals?

On this particular watch I used part number DF300CMH310 from CousinsUK. It measured 31.0mm x 1.00mm thick.

Hi,

If you change the glass, do you need to take of the bezel it looks like you can take it of? I have the same watch only with the silver dial. And this blog helpt me with the strange noise it make. I had the same problem wit a screw that was loos 🙂 now its working like it should. Only I’m thinking to replace the glass. So I need a little help 😉

Greetings from the Netherlands 🙂

Yes, you will need to remove the bezel to access the glass. It’s been a while since I’ve looked at this specific project but I believe you will have to remove the movement and push the glass out from behind once the bezel is off.

Hi, awesome work. Can you please let me know about the crystal, does this watch needs to have the bezel removed to remove the crystal ? Also, mine measures 30.6 with a calipers measure at the edge where it meets the bezel though is the exact same watch as yours, are you sure the 31mm crystal fits ? Thanks.

You have to remove the bezel to take the glass out. It’s been a while since I’ve looked at this specific project but I believe you will have to remove the movement and push the glass out from behind once the bezel is off. Removing the glass and measuring it is the best way to get the proper size.

dont know if it is usefull after all the time that has passed but here it goes 🙂

the bezel is what pushes the glass in place, When you take the movement out you can push the crystal and the bezel of the case with a die of the crystal press and some force.

The crystal is conical and gets pushed on to the gasket by the bezel, That is why the crystal seems to be smaller when you mesure the inner bezel diameter.