This post documents how to prepare an automatic mainspring and barrel while servicing a watch.

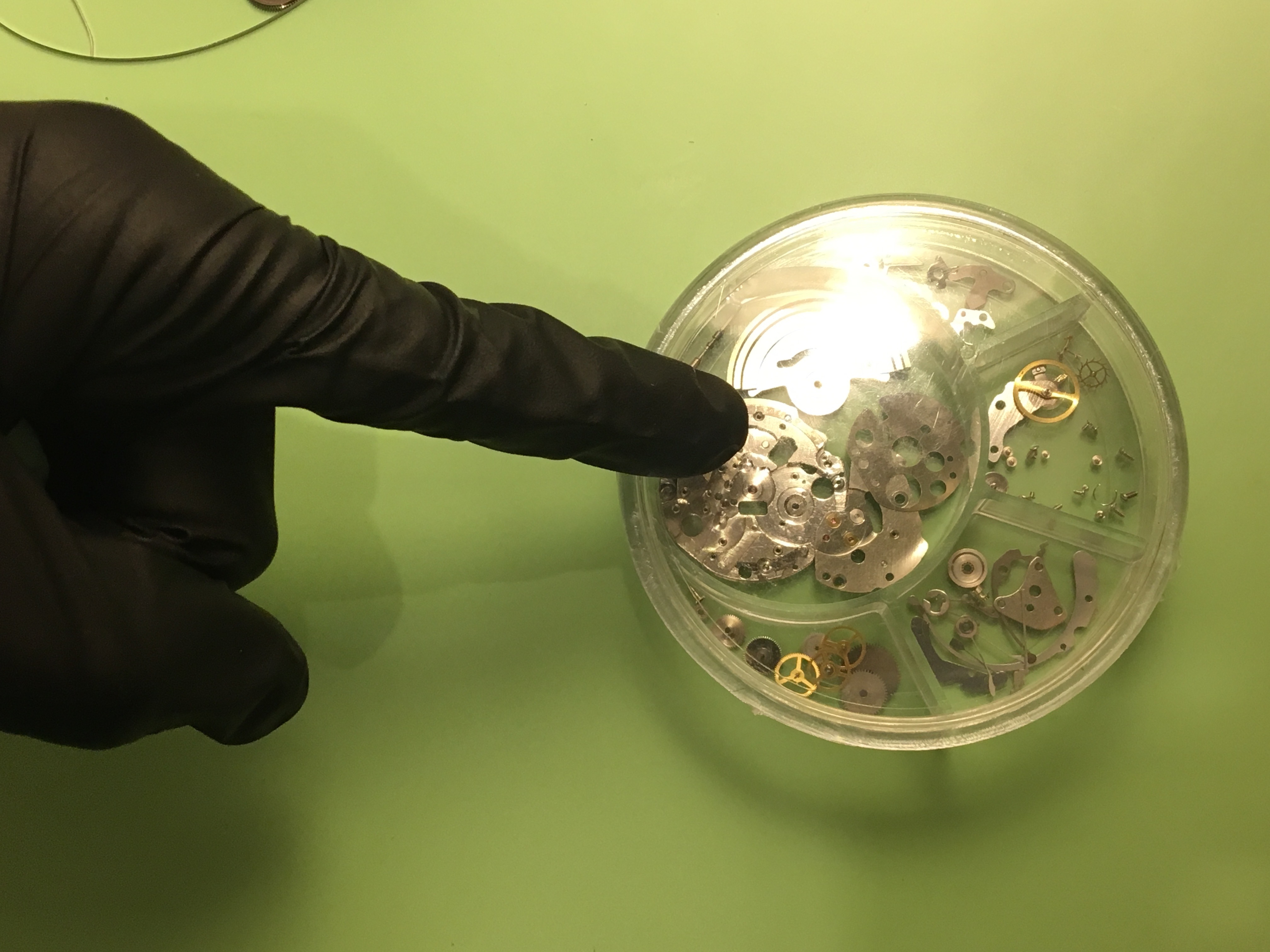

To begin, make sure you have secured all your watch parts just in case the mainspring accidentally shoots across your workbench. Parts will be strewn all over the place and you’ll have a much bigger chore than servicing a watch! Take it from me, I’ve had this happen more times than I care to admit. This step is an absolute must do!

With that disaster avoided, carefully pry the barrel cover off using your fingernails. Lubricants inside the barrel assembly become sticky as they age. This causes a significant amount of friction for the mainspring which results in a notable loss of power.

NOTE: Before going any further make note of the direction of the coil! All examples on this page are Seiko which are typically wound opposite from many other brands.

It might be necessary to clean and reuse a spring. Sometimes this can be done without issue but frequently it results in out of flat coils or kinks. These problems weaken the mainspring and cause it to rub against the inside of the barrel resulting in variety of potential issues.

Other times the spring will kink and eventually break inside barrel.

The best course of action is to replace the mainspring, if one can be sourced, so that’s all I’ll cover here.

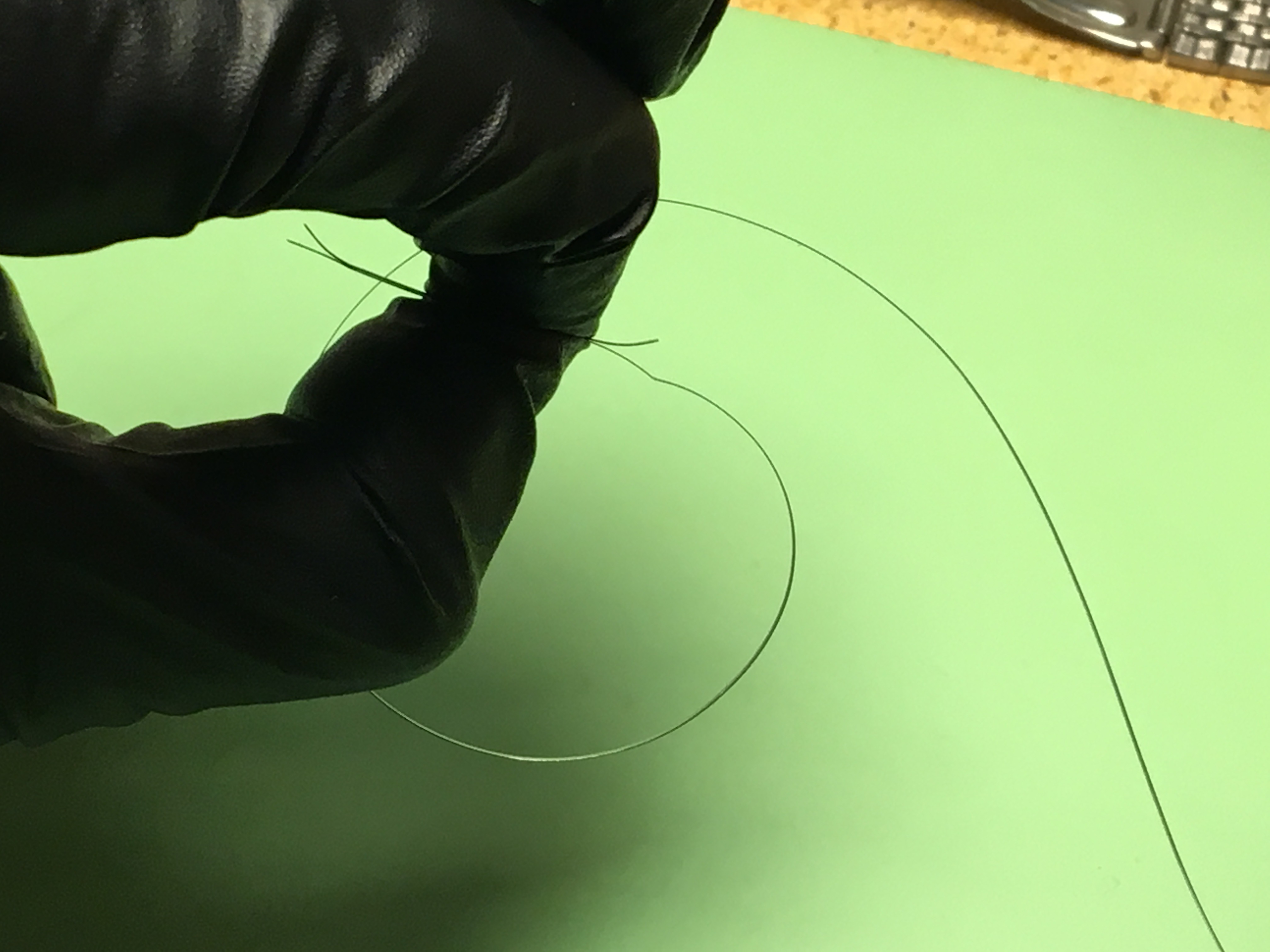

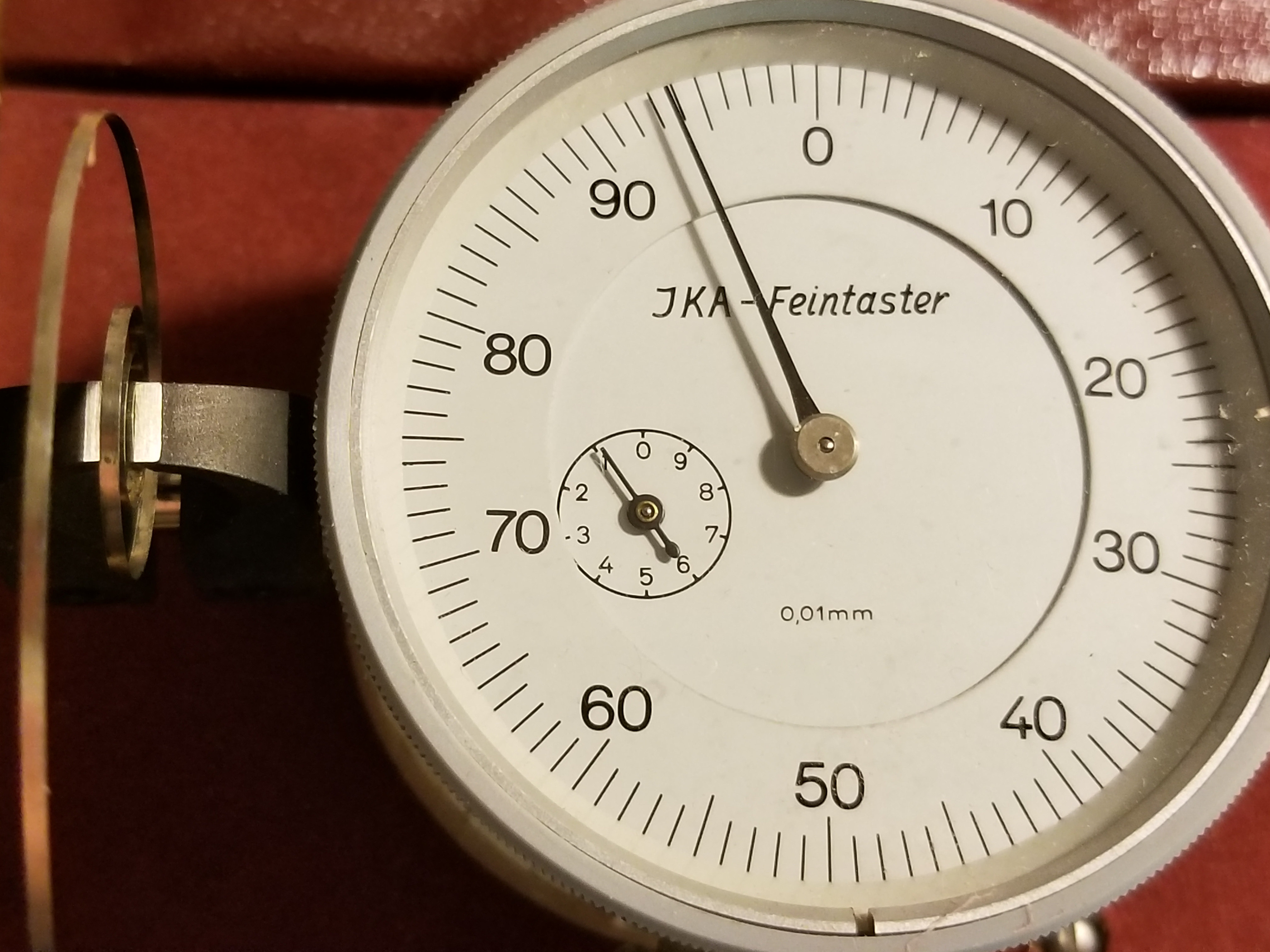

You’ll need to know the barrel diameter, height, thickness, length, and type of the original spring. The barrel diameter, height, and thickness are simple measurements to take but the length will need to be approximate due to difficulty straightening the coils.

The type generally refers to the end-piece of the spring. Most examples you’ll see on this site are of the type ‘automatic’ which means they have a small ‘Y’ shaped tail which forms a slip-clutch when fully wound inside the barrel.

Once you have those measurements go ahead and order the replacement spring and clean the barrel, arbor, and cap thoroughly.

When the new spring arrives you’ll need to prepare for the installation. I like to use 3 types of lubricant inside the barrel during assembly: Moebius 8217 natural grease, 8141 natural oil, and D-5 microgliss.

Apply 3 dabs of 8217 grease on the barrel walls at about 2, 6, and 10 o-clock. This will help the tail of the spring stick to the barrel wall while still allowing it to slip before over-winding. Be careful not to get any on the floor of the barrel as this will adversely affect the release of energy form the coils.

Spread a small amount of 8141 oil onto the floor of the barrel. Easy does it; a little goes a long way!

It is difficult to see in this picture but I also applied a very small amount of D-5 around the bearing surface for the lower end of the arbor. To recap:

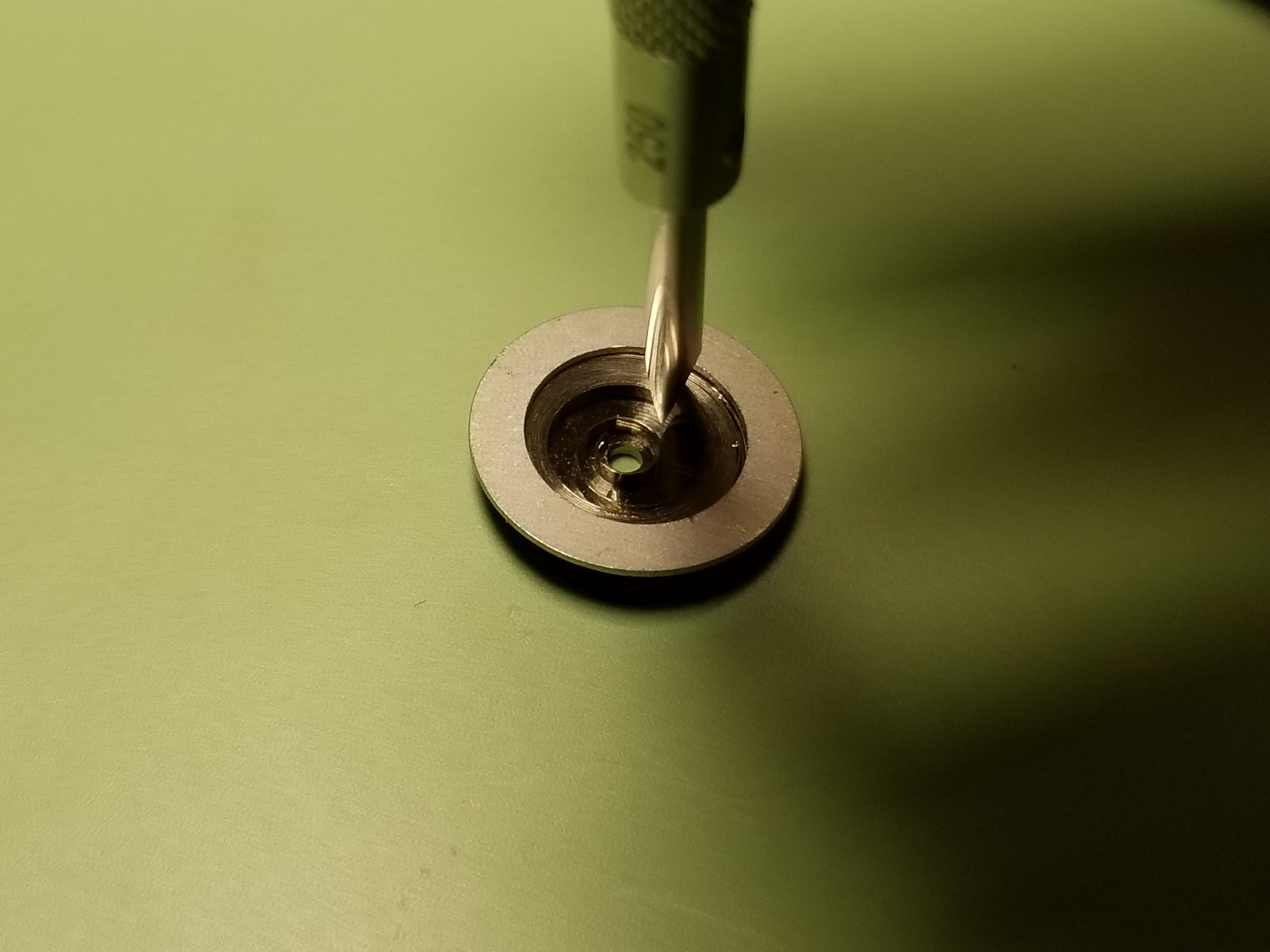

Fit the replacement spring and its holder onto the barrel.

Now using the blade of a screwdriver very carefully push the spring downward into the barrel from the holder.

Install the arbor into the smallest coil and apply a small dab of D-5 to its upper bearing surface. Apply a small dab of 8141 directly to the inside of the coils in a couple of places and a little more across the top of the spring. Again, a little bit goes a long way so just a small drop will do it.

Finally, snap the barrel cover shut; I find it is easier to use the flat portion of some tweezers. Once you hear it snap shut inspect it carefully to make sure the seal is closed tightly all the way around the barrel. While you are inspecting your work it would be good to take a little bit of Rodico and make a final detailed cleaning of the exterior.

Site Feed

Site Feed

I disassembled my first watch movement yesterday. I destroyed the barrel spring in the process. The movement was an ST 3600 Chinese. I couldn’t get the lid off the barrel so I used the wrong tools to open it. Dinged it up. I messed up the teeth on ratchet on the barrel. The spring shot out of the barrel. A complete disaster. I got it back together but I need a new barrel spring assembly complete. I will have to order a complete movement to get the parts. I plan to reassemble the movement and use it to practice on. Learning curve is expensive.